An experiment with a spiral feed mechanism

Overview

This was one of the most fun projects I’ve worked on: mechanical, hands-on, and full of iteration. What started as an exploration of 19th-century spiral feed systems evolved into a vault door, a fully functioning locking mechanism that translates rotational motion into a precise, controlled linear feed.

Inspired by historical drill mechanisms, my team (Trun Ramteke and Benji Welner) and I reimagined the spiral feed as the core of a vault door system, where rotating a “pirate wheel” gradually extends locking arms outward, securing the door with a single smooth motion.

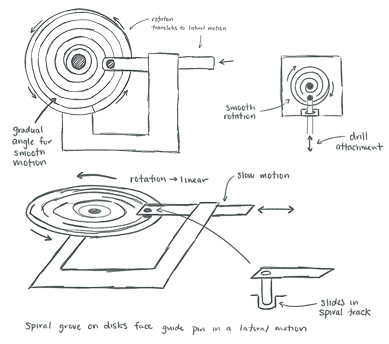

Research and Concept Development

Our concept originated from early spiral feed drilling machines, which used a grooved disk and pin to convert rotary motion into steady linear motion. This principle offered both simplicity and elegance, a single continuous motion that produces consistent force.

In reinterpreting that idea, we wanted to channel the same controlled motion into a completely new context. The spark came unexpectedly, from a bathroom lock in the Cantor Arts Museum, where we noticed how a sliding bolt’s movement corresponded to the rotation of an exterior “occupied” indicator. That direct coupling of rotation and translation became the foundation for our vault concept.

First Prototype

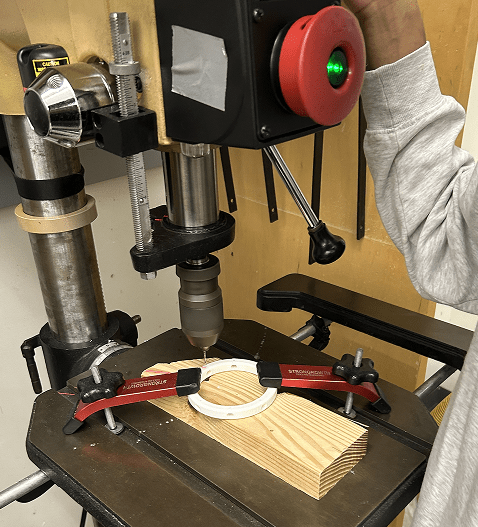

Our first prototype prioritized speed and understanding. Built using layered 2.5D laser-cut wood, it simulated the spiral geometry while allowing us to visualize and test motion paths quickly. We used off-the-shelf parts like metal screws and plastic pins to fill gaps and accelerate iteration.

The goal wasn’t polish, it was intuition. We wanted to see how friction, alignment, and pin constraints behaved before committing to more complex materials or geometries.

Second Prototype

Our second prototype took a major leap: we 3D printed the spiral and frame as a single, vertical unit. This reduced friction dramatically and eliminated many assembly variables. The vertical orientation introduced new spatial constraints but also opened possibilities for integrating it into more compact, aesthetic designs.

The stand design reflected 3D printing constraints, wide at the base for stability, but open and angular to save material and reduce print time. A last minute LEGO-inspired plus-axle connector joined the rotating spiral to the arm mechanism, allowing modular assembly and easier replacement of individual parts.

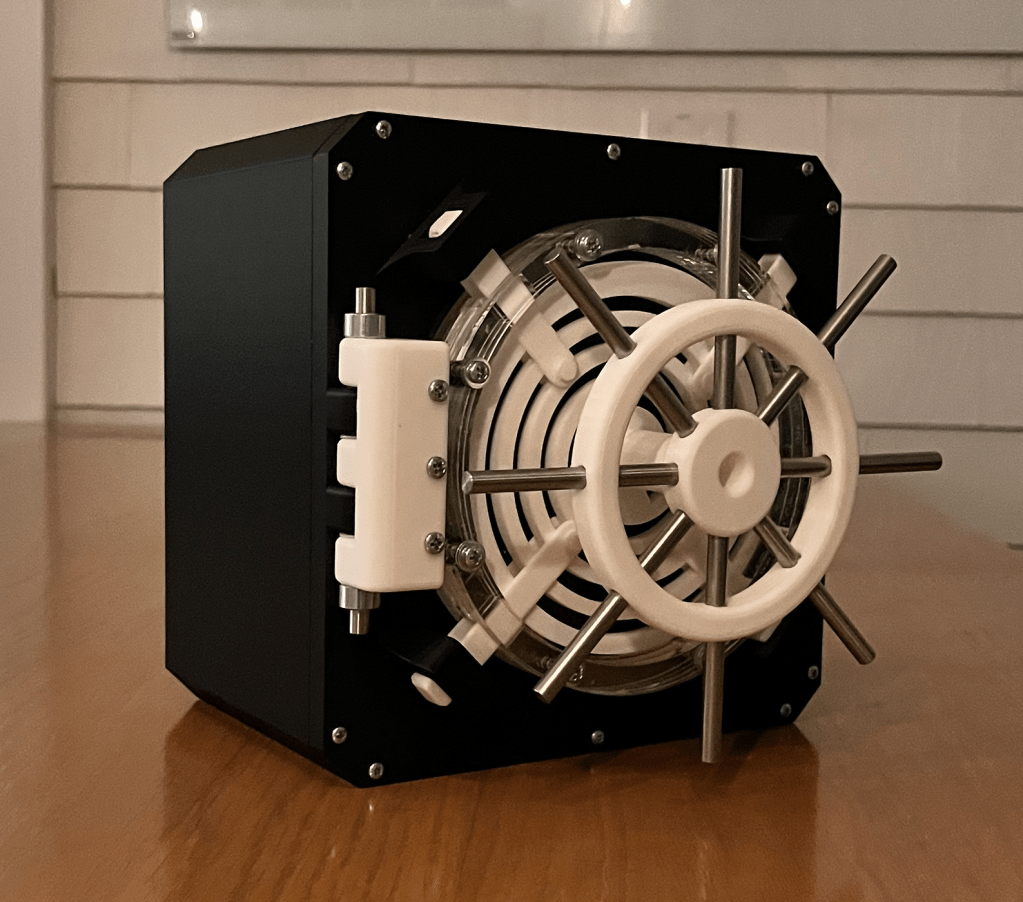

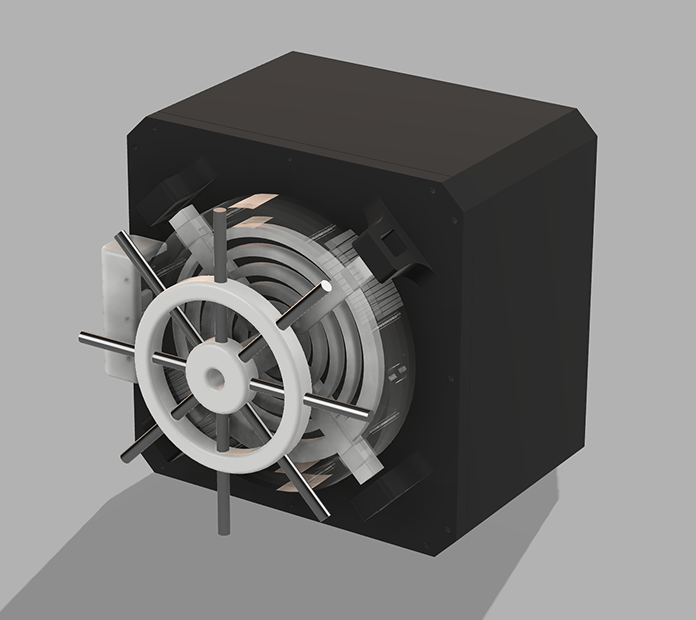

Final Prototype

Our final iteration brought everything together. We combined 3D-printed components, laser-cut acrylic panels, and metal fasteners into a cohesive mechanism that felt both functional and precise. The acrylic walls provided transparency for demonstration, while the 3D-printed spiral at the center acted as the mechanical core.

Small design details made a big difference, from tolerance tuning and stacked acrylic layers (0.236” per layer) to the embedded magnets that gave the door a satisfying “click” when closed. We refined the spiral several times to achieve jam-free, repeatable motion, and used a consistent fastener system for easy disassembly and maintenance.

Design Process

We began with a series of group sketches and motion studies, exploring how different spiral geometries could translate rotation into linear travel without jamming. Each sketch tested new arm placements, groove depths, and pin tolerances. We analyzed how varying spiral pitch and radius affected the smoothness and range of motion, informed by both precedent mechanisms and our own trial runs.

Once we had a promising geometry, we modeled the system in Fusion 360, building parametric sketches for the spiral and arms. These CAD models allowed us to experiment with groove curvature and simulate arm movement before committing to a physical build.

We used force diagrams to visualize how torque from the wheel translated into outward force along each arm. These studies helped guide later design decisions, like spiral steepness, material choice, and support thickness.

Throughout this process, inspiration came from everyday mechanisms, door bolts, windmills, etc., all devices that turn motion into security. The resulting spiral took on a sculptural, almost architectural quality: part mechanical system, part design object.

Mechanism and Performance

Turning the pirate wheel rotates the spiral, which drives four locking arms outward in unison. Each arm slides smoothly within its guide, extending into sockets on the vault’s perimeter. When reversed, the spiral retracts the arms, unlocking the mechanism.

Challenges and Iteration

Several engineering challenges shaped the final design.

- Fastener cost and scale: our early collar set screws exceeded the budget, so we redesigned the joints using drilled clearance holes and headless screws, simpler, smaller, and just as effective.

- Arm geometry: through three iterations, we adjusted thickness, width, and fillets to reduce wobble without introducing friction.

- Tolerance control: each printed spiral required minor re-tuning for alignment, leading to improved understanding of real-world print tolerances and hardware fit.

Reflection

What made this project so enjoyable was how mechanical design and storytelling overlapped, taking a century-old mechanism and turning it into something playful, tactile, and functional. It was a hands-on experiment in iteration, where every prototype taught us something new about friction, fit, and form.

Our final build blended multiple materials, fabrication processes, and design decisions into one cohesive system. From the satisfying click of the magnets to the smooth rotation of the wheel, it felt like a complete, intentional product, not just a class exercise, but a true mechanical experience.