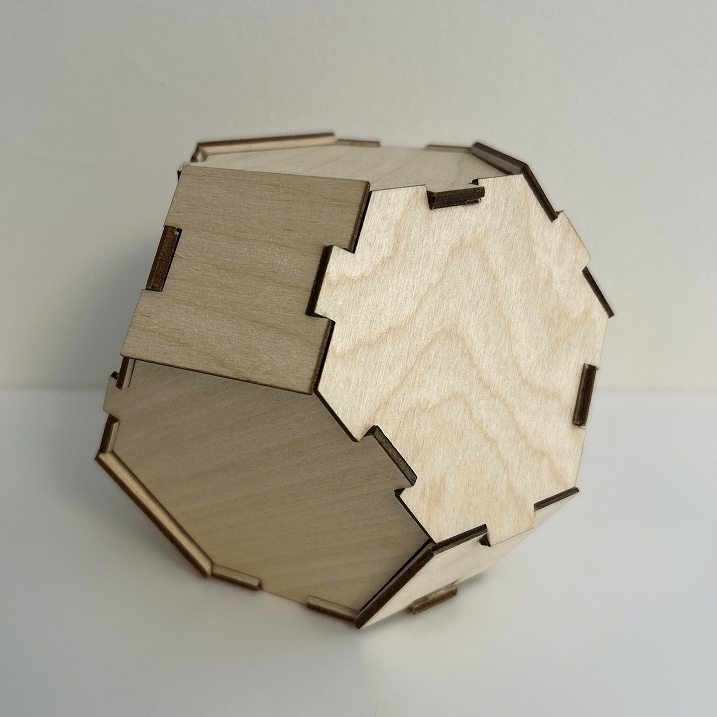

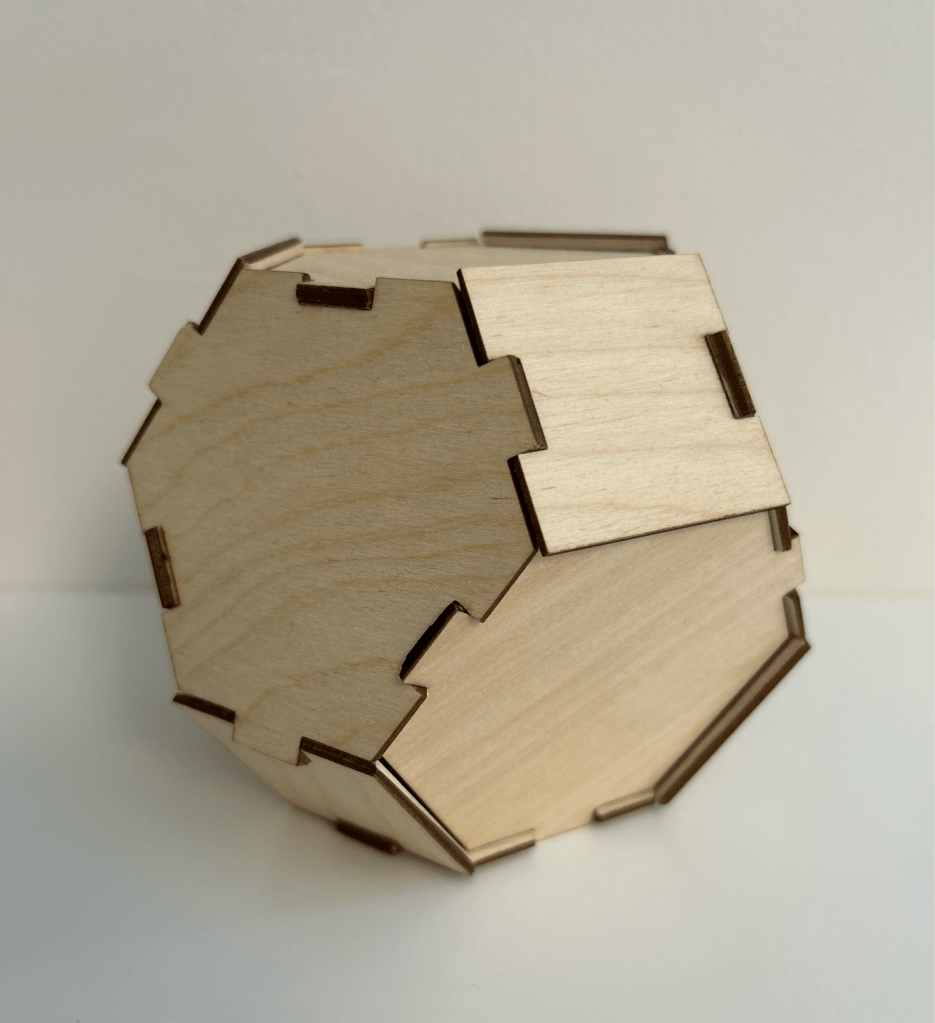

A laser-cut truncated octahedron built for efficient volume and precision fit

Overview

This project was one of my favorites, simple in concept, but surprisingly rewarding to design and build. The challenge was to create a non-rectangular box that maximized internal volume while remaining manufacturable using laser-cut plywood and friction-fit connections.

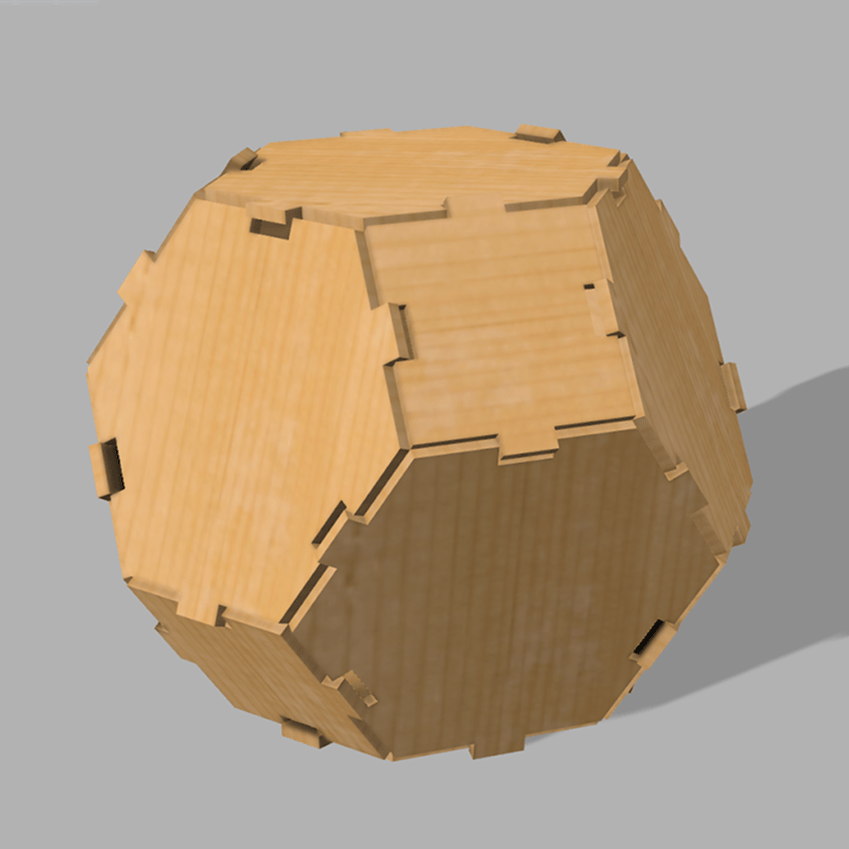

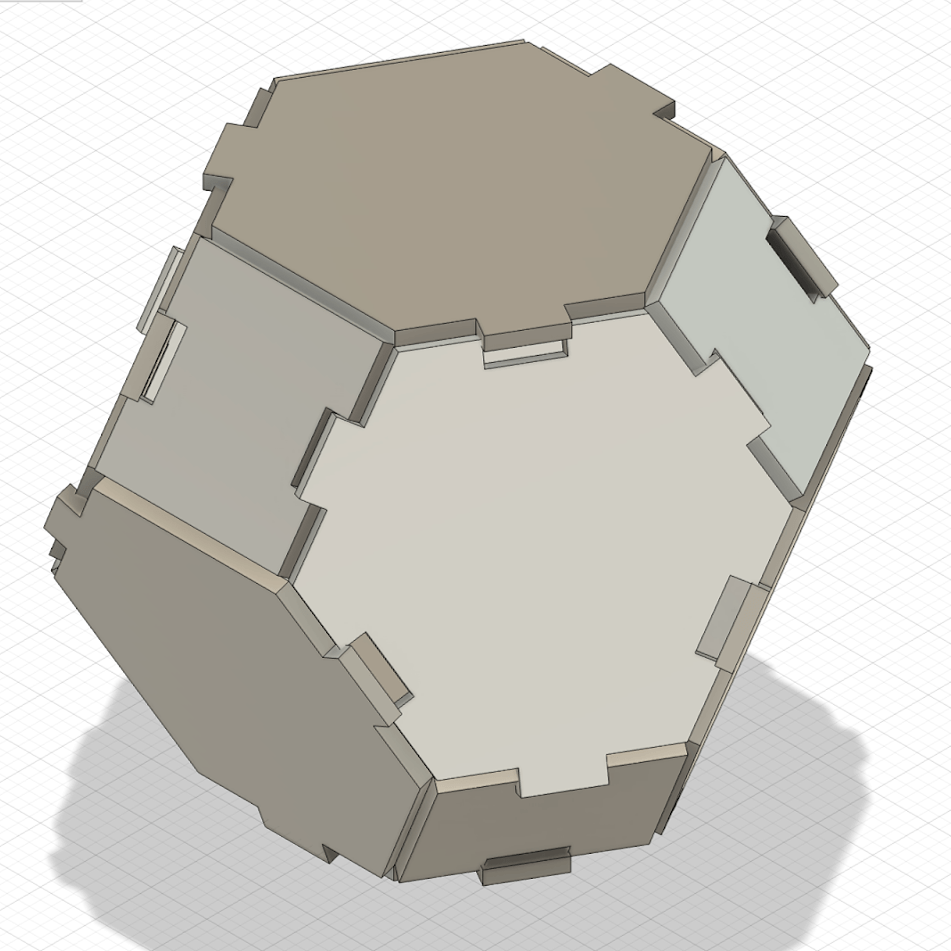

I decided to go all in on a truncated octahedron, a shape that’s geometric, efficient, and just weird enough to stand out. It’s almost sphere-like, which makes it great for volume, but still made entirely of flat hexagonal and square faces, so it could be built precisely from 2D laser-cut parts.

Design Process

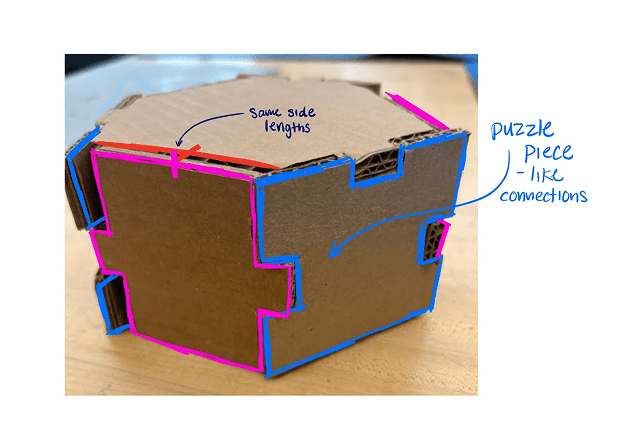

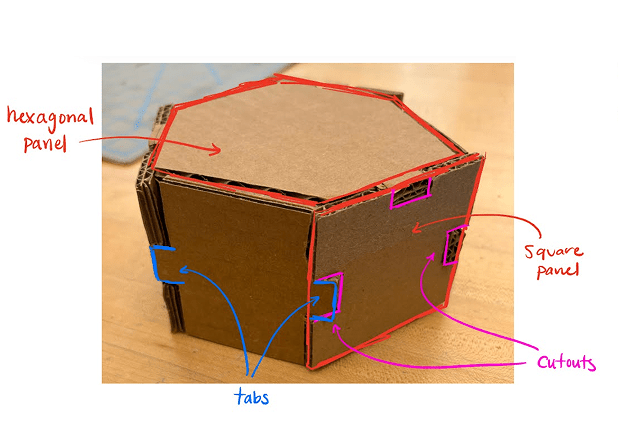

I started with sketches that explored how to transition from circular forms to hexagonal geometry, trying to capture the roundness of a sphere in a flat-sided, manufacturable form. Once I settled on the truncated octahedron, I built cardboard prototypes to visualize how the faces would come together and how friction joints could lock without glue or screws.

Next, I moved into CAD, creating parameterized sketches in Fusion 360 for the square and hexagon panels. To make the pieces fit tightly, I ran a kerf test to measure how much the laser removed during cutting. After several tests, I found that adding +0.03 inches to each slot gave the perfect snug fit, tight enough to hold, but not so much that assembly required force.

Fabrication and Assembly

I went through several iterations to refine how the pieces fit together and how efficiently they could be cut from the sheet. The first version used a dense set of friction tabs to guarantee stability, but during assembly I found that the tight tolerances and number of joints made alignment difficult, some faces didn’t meet perfectly, even though the structure was strong.

After testing the fit, I created a second version with fewer, better-positioned tabs and slightly wider slots. This simplified the assembly while maintaining strength and precision. The updated faces slotted together much more cleanly, producing a sharper overall geometry and a more consistent finish.

Each iteration helped me fine-tune not just the connections, but also how the design balanced manufacturability, stability, and visual clarity. The final assembly came together smoothly, no glue, just precise friction-fit joints, and captured exactly what I was aiming for: a clean, efficient structure built from a complex geometric form.

Reflection

Iterating through multiple versions of this design taught me how small adjustments can completely change how a form comes together. Each round of cutting and assembly gave direct feedback, how friction tabs behaved, how faces aligned, and how even a few thousandths of an inch in kerf could make the difference between a perfect fit and a forced one. What I loved most about this project was how hands-on it was. It wasn’t about complexity, but about precision — refining geometry through trial and error until everything felt right.

Volume to Surface Area Ratio

Truncated Octahedron V/SA: 0.70 (SA = 72.9 in², V = 50.8 in³)

V/SA Comparison:

| Calculation | V/SA to with same SA | V/SA ratio with same V |

| Sphere | 0.80 | 0.77 |

| Cube | 0.58 | 0.62 |