A spring-powered launcher engineered for accuracy, consistency, and repeatable reloading.

Overview

For the final project in ME 102, my team (Trun Ramteke and Benji Welner) and I designed and built a spring-powered ping pong launcher capable of consistently shooting a ball 8 feet into a 4-inch target, reloading at least five times without touching the balls, and doing so smoothly and repeatably.

This project combined mechanical design, fabrication, testing, and iteration into a single system that had to work reliably under real constraints. We spent an intense week in the PRL refining the mechanism until it felt intentional, and more importantly, met all the constraints.

Design Process

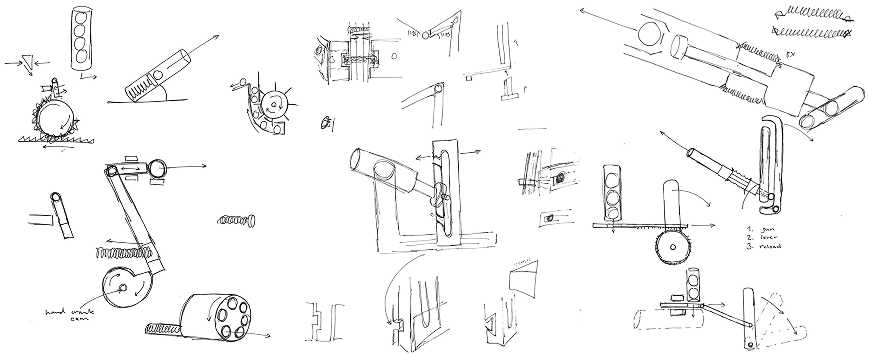

We began with extensive sketching and ideation, exploring different ways to store energy in springs, release it consistently, and reload without manual ball handling. Early concepts ranged from simple linear plungers to more complex lever and gear-driven systems.

As a team, we broke the problem down into subsystems — launching, reloading, aiming, and mounting – and tackled each independently before integrating them into a cohesive design. CAD became a critical tool here, allowing us to prototype geometry quickly and understand how tolerances and alignment would affect performance.

Prototyping and Iteration

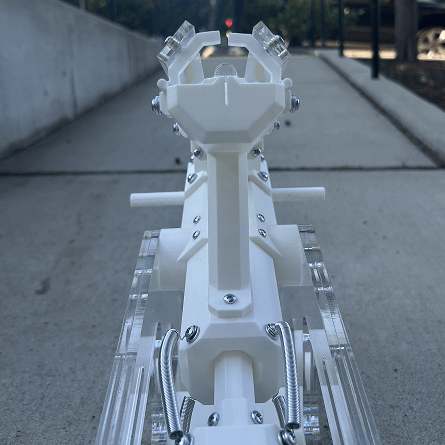

Our first three prototypes focused almost entirely on the firing mechanism. We iterated on barrel geometry, spring housing, and ergonomics, eventually arriving at a handheld launcher with an octagonal barrel and side-mounted spring modules. While functional, this form struggled with consistency and mounting stability.

Through testing, we realized that complexity was hurting performance. We reduced the number of springs from eight to four, achieving the same launch distance while simplifying the mechanism and improving reliability. From there, we shifted focus toward mounting and repeatability rather than raw power.

Reloading and Consistency

To meet the reload requirement, we designed a five-shot gravity-fed reload system. A sliding handle both blocks and releases balls from the reservoir, ensuring that only one ball enters the barrel at a time. Chamfered surfaces guide excess balls back into the reservoir during reload, preventing jams.

Because ping pong balls are extremely light, recoil introduced unexpected issues: without constraints, balls could bounce out of the reservoir. We solved this with pivoting guards that restrict ball movement while still allowing smooth feeding.

Final Prototype

The final launcher combined 3D-printed components, laser-cut acrylic, and off-the-shelf hardware into a polished, table-mounted system. We added heat-set inserts for durability and redesigned the stand using laser-cut parts to improve alignment and reduce wobble.

A guiding track in the stand constrains both vertical and lateral motion of the striking rod, significantly improving shot consistency by limiting variability from both human input and manufacturing tolerances.

Testing and Performance

We dialed in performance through extensive testing; adjusting barrel angle, clamp placement, added mass, and even operator technique. After repeated iterations, the launcher could reliably hit the target and reload smoothly across multiple shots, meeting all project constraints.

This testing phase reinforced an important lesson: simple, well-tuned mechanisms often outperform complex ones, especially when consistency matters more than raw output.

This project was a deep dive into iterative mechanical design. From sketching to CAD to fabrication, every decision had visible consequences in the final behavior of the system. Working through tolerance issues, over-engineering pitfalls, and real-world constraints gave me a much more intuitive understanding of how complex machines come together.

It’s one of the projects I’m most proud of, not because it’s flashy, but because it works — consistently, thoughtfully, and as a complete system.